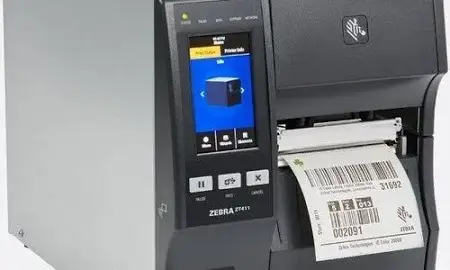

Specialized equipment called thermal printers use heat to print images on paper. Because thermal printers don’t need toner or ink cartridges like conventional inkjet or laser printers do, they are an affordable and low-maintenance choice for a lot of organizations. Thermal printers come in two primary varieties: direct thermal and thermal transfer, each with a different printing mechanism.

How Thermal Printers Work

- Direct Thermal Printers: Printers that use direct thermal technology operate by directly heating paper that is thermally sensitive. The intended picture or text is produced when the thermal paper passes over the printer’s thermal head and the heated parts turn black. For receipts, tickets, and shipping labels, direct thermal printers are a common choice due to their ease of use and lack of ink or toner requirements. Nevertheless, if the prints are exposed to heat, light, or other environmental elements over time, they may fade.

- Thermal Transfer Printers: On the other hand, thermal transfer printers use a thermal print head to imprint wax or resin-based ink onto paper via a ribbon. This process yields longer-lasting, more resilient images that are impervious to heat, water, and fading. For printing barcodes, shelf labels, asset tracking, and other applications where printout longevity is crucial, thermal transfer printers are perfect.

Benefits of Using Thermal Printers

- Speed: Labels and receipts can be printed by thermal printers in a matter of seconds due to their extreme speed. They are therefore ideal for settings with lots of activity.

- Quality: They provide long-lasting prints, particularly thermal transfer prints, that are impervious to fading and smudging.

- Cost-Effectiveness: Compared to conventional printers, thermal printers offer a reduced total cost of ownership because they don’t require ink or toner cartridges.

- Dependability: Because thermal printers have fewer moving parts, they require less maintenance and have shorter downtime.

- Versatility: Depending on the printer type, they can print on a range of media, including paper, synthetic materials, and even textiles.

When to Use Thermal Printers

- Healthcare: The robustness and chemical and solvent resistance of thermal transfer printers make them ideal for patient wristbands, lab labels, and prescription labels.

- Logistics and Shipping: Due to its speed and capacity to generate barcodes that are simple to read, direct thermal and thermal transfer printers are utilized for asset tagging, inventory management, and shipping labels.

- Production: Thermal transfer printers are the best tools for producing durable labels for goods, particularly those that must withstand harsh environments or be durable.

Choosing the Right Thermal Printer

- When deciding on a thermal printer, consider the following factors:

- Durability of Prints: Thermal transfer printers are a superior option if you require prints that are resistant to environmental influences and stay longer.

- Volume: The effectiveness and speed of direct thermal printers may be more advantageous in high-volume environments.

- Cost: Direct thermal printers are often less expensive up front, but thermal transfer printers may be more cost-effective in the long run for applications where the labels must endure rough handling.

- Media Compatibility: Ensure the printer supports the types of media you plan to use, whether it’s paper, synthetic materials, or textiles.

Conclusion

For a variety of purposes, thermal printers provide an effective and adaptable printing solution. Businesses may choose the kind of printer that best meets their needs by being aware of how they operate and the advantages they offer. There is a thermal printer out there that is ideal for the task, regardless of whether you’re seeking for durability and quality in industrial settings or speed and efficiency in retail settings. Thermal printers are still a popular option for many businesses due to their dependability and affordability, demonstrating that sometimes the right equipment really can make all the difference.