Have you ever peeled a label off a package or container only to find the text smudged, the barcode unreadable, or the colours faded? In many industrial, retail, and logistics operations, labels have to survive long journeys, harsh environments and repeated handling. A label that fails to withstand its environment can mean missed scans, mis-shipments, lost inventory, and frustrated staff. That’s where the power of a thermal transfer printer comes through – it isn’t just about printing a sticker, it’s about creating a label that lasts.

Understanding the Technology

At its core, a thermal transfer printer uses a heat‐activated ribbon to transfer ink onto a substrate (label material). Unlike direct thermal printing — where heat alone triggers a chemical change in the label paper — a thermal transfer process melts ink (wax, wax-resin or resin) from a ribbon and adheres it to the label surface (or fuses it into the synthetic substrate). When the right ribbon, printhead temperature, and substrate are matched, the result is a printed image or text that bonds strongly with the surface and offers impressive resistance to wear.

This level of bond is what gives the thermal transfer printed label its durability. It is no surprise that leading industrial analysts state that thermal transfer printing is the preferred choice when labels must last more than six months or withstand extreme conditions.

To make this more concrete: if your pallets travel for weeks, your asset tags stay on equipment outdoors, or your chemical drums move through rugged warehouses — a thermal transfer printer is the smart choice.

Wondering why your POS machine isn’t printing receipts? Discover the top issues and fixes in “Top 7 Reasons Your POS Machine Not Printing Receipts — And How to Fix Them”.

Why Label Durability Matters

You might wonder: “Isn’t a regular label good enough for many applications?” The answer is that in some uses, yes, but in many others, durability is critical. Here’s why:

Operational Reliability

Labels carry barcodes, product IDs, shipping addresses, compliance information and many other critical data points. If the printing fades, smudges or becomes unreadable, you risk failed scans, manual overrides, delays or even regulatory issues.

Cost of Failure

When a label fails, it is not just a wasted sticker. It may trigger a return, a mis-route, a quality control alert, or a compliance breach. These mistakes add hidden costs — staff time, corrective action, and higher scrap rates — costs that a durable label can help avoid.

Long Lifecycle Requirements

Certain applications require a label to stay legible for years (e.g., equipment tracking) or to retain clarity through exposure to chemicals, heat, cold, UV light or abrasion. A standard label won’t cut it; that’s where a thermal transfer printer shines.

Brand and Professional Image

For manufacturers, retailers and distributors, poor labels can communicate low quality. Crisp, durable labels reflect a professional image, better customer experience and improved trust. This is especially true in luxury goods, pharmaceuticals or regulated industries where every detail matters.

Key Features of Thermal Transfer Printing That Enhance Durability

1. Ribbon Technology Options (Wax / Resin / Hybrid)

The ribbon in a thermal transfer printer is the unsung hero of durability. Depending on the application, you can choose:

- Wax ribbons, suitable for general-purpose printing on paper labels.

- Wax-resin hybrids, offering moderate resistance to chemicals and abrasion, on synthetic labels.

- Full resin ribbons, designed for extreme conditions — heavy abrasion, chemicals, solvents, outdoor exposure.

By selecting the appropriate ribbon and substrate combination, a thermal transfer printer ensures the print remains intact.

2. Substrate Material Compatibility

Durability isn’t only about ink — it’s about the label material too. Paper is inexpensive but less tough. Synthetic materials like polypropylene, polyester or vinyl offer much greater strength. A thermal transfer printer can print on all of these, making it highly versatile.

3. Print Head & Heat Management

Because the thermal transfer process applies heat and pressure, it ensures that the ink flows into the substrate rather than merely sitting on top. This deeper bond means the label is less prone to peeling, smudging or fading. The result is a print that looks better and lasts longer.

4. Environmental Resistance

Labels printed with a thermal transfer printer are far better equipped to deal with environmental stress: UV light, heat, cold, moisture, chemical exposure, abrasion, outdoor storage.

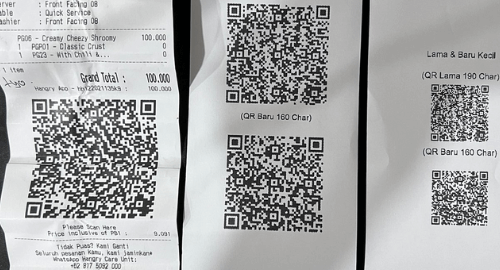

5. High Print Resolution and Barcode Clarity

Especially in supply chain, barcode readability is essential. A thermal transfer printer delivers sharp edges, precise lines, and strong contrast — all critical for high scan success rates.

Real-World Examples: Durability in Action

Manufacturing & Industrial Environments

In manufacturing plants where products go through heat, chemicals, heavy handling and often outdoor exposure, labels must endure. A thermal transfer printer is ideal for product identification, equipment tags, safety warnings and asset tracking in these environments.

Logistics and Warehousing

Moves, racking, forklifts, temperature swings — strips of adhesive labels face a barrage of stress in warehouses. Labels printed with thermal transfer technology still scan reliably, track assets and avoid misrouting. That means fewer delays, fewer errors and fewer complaints.

Healthcare and Pharmaceuticals

In hospitals and labs, labels may go onto vials, patient wristbands, packaging, or refrigerated samples. They may face sterilization, cold storage, handling, solvent exposure and regulatory demands. Thermal transfer printing supports this level of durability and traceability.

Retail and Brand Presentation

Even shelf labels, garment tags and product packaging benefit from durability. Wear and tear from handling, sunlight in display windows and repeated scanning can degrade lesser printed labels. A thermal transfer printer ensures that brand identity stays sharp and readable.

Having trouble with your printer? It might just need a cleaning — check out “Printer Not Working? It Might Just Need a Cleaning Kit” for a quick fix guide.

Why Investing in a Thermal Transfer Printer Makes Sense

When viewing label durability as a strategic investment rather than a consumable cost, the business case for a thermal transfer printer becomes clear:

Cost Savings Over Time

While consumables (ribbons, specialty labels) may cost slightly more upfront than basic labels, the saving come in fewer replacements, fewer mis-labels, fewer returns, and smoother operations. Problems from fading or peeling labels can quietly add up; a thermal transfer printer prevents them.

Reduced Downtime and Error Rates

Labels that fail cause scanning issues, manual interventions, delays and lost productivity. Using a thermal transfer printer reduces those failures, meaning smoother workflows and better reliability.

Compliance and Traceability

If your industry (food, pharma, manufacturing) demands strict traceability and long label lifecycles, then durability isn’t optional. A thermal transfer printer delivers the quality required for regulatory audits, recalls and quality systems.

Future-Proofing Your Labeling Strategy

As operations expand, globalise, or expose goods to harsher environments (cold chain, outdoor logistics), choosing a thermal transfer printer means you already have the capability, rather than having to retrofit later. It’s a smart, forward-looking choice.

Improved Brand Perception

Durable, crisp labeling also sends a message — to customers, partners and internal teams — that your operations are modern and professional. In a crowded marketplace, the quality of your packaging and identification matters.

Selecting the Right Thermal Transfer Printer: What to Consider

Not all thermal transfer printers are created equal. If you’re ready to invest in one, here are key factors to guide your decision:

Print Volume and Speed

If you print hundreds of labels per day, you’ll want a model with faster throughput. If you only occasionally print, a desktop or lower-volume machine may suffice. The same technology still applies, but the scale differs.

Resolution and Print Quality

For fine text, small barcodes, or high-density graphics, look for a 300dpi model or better. High resolution matters when legibility and scanning accuracy are essential.

Substrate and Ribbon Compatibility

Make sure the printer supports the label materials you need (paper, polyester, vinyl, etc.) and that ribbon types (wax, wax-resin, resin) are compatible. Matching ribbon type to substrate and environment is where durability is earned.

Environmental Conditions

Will labels face heat, cold, chemicals, outdoor exposure, abrasion or light? If yes, invest accordingly in a printer designed for industrial usage rather than entry-level. As one guide states, choose thermal transfer when you need labels lasting more than 6–12 months.

Connectivity, Software and Integration

Look for network connectivity (Ethernet/WiFi), compatibility with your label design software, driver support and ease of use. Long-term sustainability depends on ease of integration and operation.

Total Cost of Ownership (TCO)

Don’t evaluate only the purchase cost. Factor in ribbons, label media, maintenance, downtime risk and replacement cost. A high-quality thermal transfer printer will save more in long-term costs than cheaper alternatives.

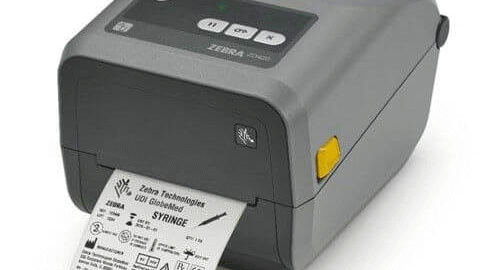

Example Product: Reliable Model

A good reference model can help benchmark features and quality. For instance, our Zebra ZD421T Thermal Transfer Desktop Printer – High Quality Barcode Printing is an example of a well-specified thermal transfer printer suited for demanding label durability needs.

Best Practices for Achieving Maximum Durability

Implementing a thermal transfer printer is only half the job — how you use it will determine label reliability and performance. Here are the best practices:

Use the Right Ribbon-Substrate Combination

Pairing a resin ribbon with a polyester label on outdoor assets yields far better durability than a paper label and wax ribbon designed for short-term indoor use. Match materials to conditions.

Calibrate Print Settings

Correct temperature, speed and printhead pressure settings ensure optimal transfer of ink and reduce waste. Poor calibration can mean faded bars, inconsistent print or premature wear.

Clean Print Heads and Maintain Regularly

Dirt, dust and debris build-up can reduce print quality and shorten component lifespan. Regular cleaning and preventive maintenance prolong the life of both the printer and label integrity.

Store Media Properly

Keep labels and ribbons in controlled environments (avoiding extreme heat, humidity or direct sunlight). Media degradation before printing can ruin a good output.

Test in Real Conditions

Before full deployment, test a printed label in the actual environment: outdoor exposure, freezer conditions, chemical exposure, abrasion, etc. If it holds up, you’re set; if not, adjust materials or ribbon.

Use Barcodes with Adequate Margins

When designing labels for durability, ensure barcode quiet zones, print contrast and verification. A thermal transfer printer only does part of the job — good label design matters too.

The Role of a Thermal Transfer Printer in Supply Chain and Beyond

As global supply chains become more complex and products travel further, durability is not optional. Whether assets are tracked in cold storage, pharmaceuticals move through complex logistics or equipment is deployed outdoors for years, the label is a silent workhorse. A thermal transfer printer ensures that the label continues to work long after less robust labels have failed.

In retail, durability supports brand integrity and ensures shelf tags remain legible even after customers handle and remove multiple items. In healthcare, durable labels support patient safety, medication traceability and regulatory compliance. In manufacturing and logistics, they enable automation and scanning efficiencies that rely on labeling technology. Essentially, the thermal transfer printer becomes the foundation for reliable communication and tracking.

Conclusion

Labels may seem like a minor detail in your workflow, but when they fail at the wrong time or in the wrong environment, the consequences ripple. A thermal transfer printer gives you the technology to print labels that don’t just look good, but last good. It delivers the durability, clarity, and reliability essential for modern operations — whether in manufacturing, logistics, healthcare, retail, or shipping.

By understanding how thermal transfer printing works, choosing the right materials, optimizing your print environment and selecting appropriate hardware, you set your labeling system up for long-term success. The investment pays off in fewer errors, fewer replacements, smoother workflows and better brand integrity. If durability matters — and in many industries it absolutely does — then a thermal transfer printer is the tool you need.

Ready to explore robust labeling solutions? Consider deploying a quality model (such as Zebra ZD421T Thermal Transfer Desktop Printer – High Quality Barcode Printing) and upgrade your label durability today.

In the world of labels, you don’t just want them to print — you want them to endure. A thermal transfer printer gives you that longevity and peace of mind.