In an age where environmental concerns are crucial, the necessity for environmentally friendly procedures has permeated all aspects of our lives, including ID card printing. Businesses and organizations in Kuwait and throughout the world are choosing greener alternatives to ID card printing as technology advances, lowering their carbon footprint and contributing to a healthier planet. This blog will look at the unique sustainable approaches used in ID card printing.

Biodegradable and Recyclable Materials

PVC (polyvinyl chloride) cards have long dominated the ID card market. These cards, on the other hand, are known for being non-biodegradable, which leads to plastic waste. Biodegradable or recyclable materials are used in eco-friendly ID card printing. These materials disintegrate naturally over time or can be recycled, lowering their environmental impact dramatically.

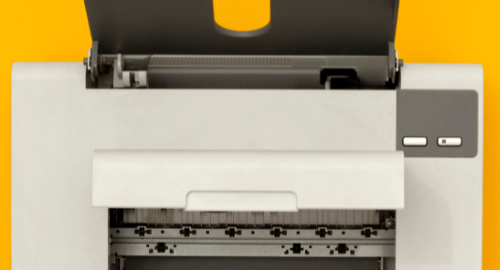

Printing Techniques That Use Less Energy

Modern printing technology enables energy-saving operations. Digital printing, for example, eliminates surplus stock by producing only the appropriate number of cards. Direct-to-card printers also generate less waste than standard offset printing methods. This efficiency not only saves resources but also cuts corporate operations costs.

Laminates and coatings based on water

ID cards have long been laminated and coated to protect them from wear and tear. Traditional solvent-based laminates and coatings, on the other hand, can have significant environmental consequences. The use of water-based laminates and coatings eliminates the discharge of hazardous solvents into the environment, making the ID card manufacturing process more environmentally friendly.

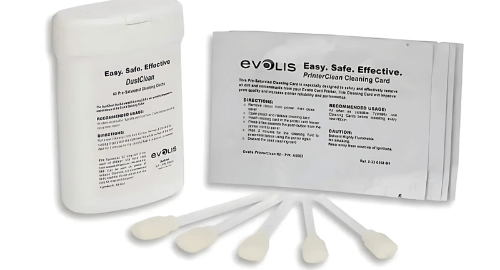

Closed-Loop Recycling Methods

Certain ID card printers are leading the way in closed-loop recycling systems, a sustainable approach that exemplifies the circular economy model. This approach entails gathering discarded or outmoded cards, shredding them, and reusing the recovered material to create new cards. This clever approach not only saves waste but also considerably reduces the demand for virgin materials, thus preserving vital resources. Manufacturers demonstrate a dedication to eco-friendliness by using this closed-loop process, addressing environmental concerns while optimizing material utilization. This recycling cycle coincides with sustainability ideals, resulting in a win-win situation that benefits both the planet and the manufacturing process.

Standards and certifications

To guide sustainable ID card printing, industry-specific certifications and standards are emerging. Companies are working hard to meet requirements that promote responsible sourcing, waste reduction, and energy efficiency. These certifications not only demonstrate a commitment to sustainability but also offer consumers clear information about the items they use.

POS Machines and Digitalization

Point of Sale (POS) machines, which are widely used for various transactions, are also contributing to sustainable practices. By embracing digitalization and reducing paper usage through digital receipts and online record-keeping, these machines help conserve valuable resources. Moreover, the shift to digital processes minimizes the need for physical documents, including paper-based ID cards, which in turn reduces waste production.

Using RFID Technology

RFID technology, a significant component in sustainable ID card printing, allows information to be embedded into cards via radio waves. This idea reduces waste by substituting a large number of single-use cards. A single RFID-enabled card may adapt to different jobs, eliminating the need for regular reprints. This not only saves costs but also streamlines operations, resulting in less administrative effort. RFID-equipped ID cards demonstrate a greener approach, matching with eco-conscious practices in today’s environmentally sensitive world, by increasing the lifespan of a single card and reducing wasteful production.

The switch to sustainable ID cards in Kuwait is an important step toward a more ecologically conscientious future. The ID card printing business is demonstrating that usefulness and sustainability can coexist by integrating biodegradable materials, energy-efficient procedures, and careful design practices. As these practices expand, the collective endeavour to go green will definitely result in a brighter, greener future.