Barcode ribbons are among the most essential label printing items in industries, where correct and reliable barcodes have become a backbone for operations. For retail, logistics, health, and manufacturing sectors, the quality of barcode ribbons directly relates to the performance of supply chains, inventory, and business management. High-quality barcode ribbons are chosen for their optimal print performance, long durability, and legibility to guarantee smooth performance.

What are barcode ribbons?

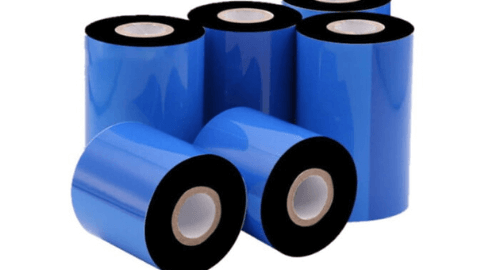

Barcode ribbons are consumables used in thermal transfer printers to produce robust and precise labels. The ribbon, made of wax, resin, or a combination of both, transfers ink onto the label by using heat. The result is a crisp, smudge-resistant barcode that can be used in most environments and applications. The selection of a barcode ribbon would depend on the label material used and on what it was being applied to.

Why Good-Quality Barcode Ribbons Are Important

1. Print Clarity and Precision: High quality barcodes are sharp, precise, and readable for bar-code scanning. Low-quality ribbons might create indistinct or incomplete prints, that creates scanning errors and, thus delays the operation. Such problems are more tedious in industries such as retail and logistic sectors, where a fast scan of a barcode becomes a necessity.

2. Durability and Longevity: labels printed with premium ribbons last for a longer time, thus withstanding environmental factors like moisture, temperature fluctuation, and chemicals. The need is great in harsh environments to be applied in warehouses, outdoor storage, and industrial settings.

3. Less Downtime: Inferior barcode ribbons may cause some problems in printers like spreading, breaking, or excessive residues collected on ribbons. Such issues do not only affect the quality of labels but also increase time devoted to maintenance and downtime. Good-quality ribbons, on the other hand, ensure smooth printer operations and reduce the number of repairs.

4. Cost Effectiveness: The high-quality barcode ribbons, while more expensive at first sight, have often proven to be more economical over the long run. With reliability, there is less reprinting, reduced wastage, and generally more efficient operation, which will save time and money.

5. Compliance with Industry Standards: High-quality barcode ribbons make sure that any industry will have consistent labeling meeting traceability, safety standards, and even regulatory compliance. Using high-quality barcode ribbons ensures that your labels meet these standards, avoiding potential fines or operational disruptions.

Explore A guide to barcode ribbons: types and comparisons.

Types of Barcode Ribbons

Recognize the various types of barcode ribbons, which can help you find the right one for your purposes:

1. Wax Ribbons: They’re a cost-effective option, usually with general-purpose printing on paper labels. They are suitable for an indoor environment with low environmental stressors.

2. Wax-Resin Ribbons: This option is versatile with some features, including being stronger and more durable than wax ribbons. They are suited to the semi-gloss and synthetic labels used in moderate environmental conditions.

3. Resin Ribbons: Resin ribbons are designed for high-performance applications and offer maximum resistance to heat, chemicals, and abrasion. They are the best choice for printing on synthetic materials and for labels exposed to harsh environments.

Tips for Choosing the Right Barcode Ribbon

- Identify Your Label Material: Ensure the ribbon is compatible with the label material to achieve optimal print quality and durability.

- Consider Environmental Factors: Select ribbons based on the conditions your labels will face such as chemical exposure, extreme temperatures, or moisture.

- Volume and Printer Compatibility: Select ribbons that match your volume and printer specifications to ensure your application functions with little wastage.

- Partner with Reputable Suppliers: Partnering with trusted suppliers ensures access to top-quality barcode ribbons and expert advice in picking just the right product for your application.

Conclusion

Investing in quality barcode ribbons is a smart move that can greatly improve the efficiency and reliability of your label printing process. Whether you need barcodes for inventory management, product labeling, or logistics tracking, using the right ribbon ensures clear, durable, and compliant labels. By prioritizing quality, you can avoid costly reprints, minimize downtime, and maintain smooth operations across your business.